IV Packing Line

COMPLETE IV PACKING LINE

LEAK TEST MACHINE

Salient Features:

-

Structure made of SS 304 rigid construction.

-

Special Nylon rubber endless belt is used for the conveyor for long life & durability.

-

Specially designed SS 304 hood for internal lighting with black & white stations.

-

Guide provision for transfer of bottles into initial 2 tracks & final 3rd track for conveying the tested products.

-

Easy & comfortable visualization position for operators for inspection.

-

Specially designed hard chrome roller with self-aligned bearings for longer life of conveyor.

-

Sitting stools arrangement for 8 persons (OPTIONAL).

-

Bowl for the dust cap at both side of the conveyor.

-

Partition after every two booth.

-

Tension mechanism is provided for adjusting the belt tension.

-

AC variable drive for variable speed as per product size. The drive is fitted in the control panel below the conveyor.

-

Usage of reliable & proven components such as Bonfiglioli/Motovario/Rotomotive/Gennext Motor, Delta make AC variable drive etc.

Operation:

-

Bottles coming from onward machine/to be loaded manually to the conveyor.

-

The bottles are automatically bifurcated into 2 adjoining tracks with the help of guide.

-

The operators pick up the bottles from the 2 side tracks. They visually inspect the bottles with the help of black and white booth with tube light on conveyor for any breakage, leakage, proper volume filled & sealed and any strange particles in filled bottle.

-

After inspection the bottles are placed in the central track, which is transfer for further operation.

ONLINE VISUAL INSPECTION CONVEYOR

Salient Features:

-

Structure made of SS 304 rigid construction.

-

Special Nylon rubber endless belt is used for the conveyor for long life & durability.

-

Specially designed SS 304 hood for internal lighting with black & white stations.

-

Guide provision for transfer of bottles into initial 2 tracks & final 3rd track for conveying the tested products.

-

Easy & comfortable visualization position for operators for inspection.

-

Specially designed hard chrome roller with self-aligned bearings for longer life of conveyor.

-

Sitting stools arrangement for 8 persons (OPTIONAL).

-

Bowl for the dust cap at both side of the conveyor.

-

Partition after every two booth.

-

Tension mechanism is provided for adjusting the belt tension.

-

AC variable drive for variable speed as per product size. The drive is fitted in the control panel below the conveyor.

-

Usage of reliable & proven components such as Bonfiglioli/Motovario/Rotomotive/Gennext Motor, Delta make AC variable drive etc.

Operation:

-

Bottles coming from onward machine/to be loaded manually to the conveyor.

-

The bottles are automatically bifurcated into 2 adjoining tracks with the help of guide.

-

The operators pick up the bottles from the 2 side tracks. They visually inspect the bottles with the help of black and white booth with tube light on conveyor for any breakage, leakage, proper volume filled & sealed and any strange particles in filled bottle.

-

After inspection the bottles are placed in the central track, which is transfer for further operation.

AUTOMATIC HORIZONTAL (TOP) STICKER LABELING MACHINE

Machine Description:

-

The unit is made Compact & Versatile as per GMP norms.

-

Applicator controlled by PLC and Operated with HMI.

-

Various label Height position adjustment with help of S.S sliding pipe assembly.

-

Imported sensor makes Leuze/Sick.

-

All automation parts like VFD, HMI and PLC system CE certified and Imported.

-

Specially design dispenser for Accurate label Dispensing.

-

All moving parts cover by safety guard.

-

User friendly & very less maintenance.

-

Specialized Belt conveyor for product transmission.

-

Specialized Imported sensor for accurate Pouch sensing.

-

Special Material sponge for uniform label pressing.

-

All M.S exposed parts will be covered with S.S cover or Powder coated.

-

Heavy and Rigid Structure and Machine with Matt Finished.

Component Description:

-

VFD DRIVES- MITSUBISHI

-

PLC- MITSUBISHI

-

HMI- MITSUBISHI

-

SENSOR SET- SICK MADE IN GERMANY

-

MOTOR GEAR BOX- ROTOMOTIVE

Advance Features:

-

Touch Screen operated HMI CE Certified.

-

Special functions like Product Delay, Label Length, label speed and Multiple Program facility for easy and fast operation.

-

Bottles/Minute and Total count facility for Output Records.

-

Password Protection on customer request.

-

Easy to use adjustments, requiring a minimum tools or change of parts.

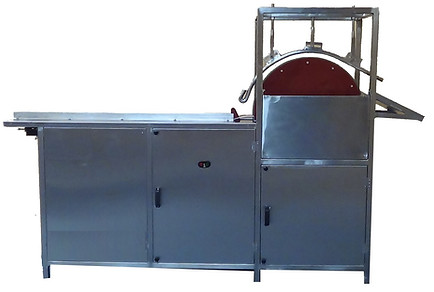

AUTOMATIC HORIZONTAL FLOW WRAPPING MACHINE

Salient Features:

-

The machine is manufactured or developed accordance with GMP standards.

-

Rigid vibration free construction,noiselessfor trouble free performance.

-

The structure is made of MS and cladded with SS 304.

-

The contact parts are made of SS 304.

-

All the Bearings are makes of SKF OR NTN.

-

Cross sealing heaters operate on 220 volt.

-

Specially designed jaw mechanism.

-

Conveyor made of specialized positive pusher on chain. In-feed conveyor 2 meter long for easy feed of our product.

-

MAIN ON/OFF SWITCH: This is a switch to switch ON/OFF power to the machine.

-

EMERGENCY SWITCH: This is a push button to stop the machine immediately.

-

All Electrical Components are ISI Marks.

-

Gear & sockets EN-8.

-

Tower light.

-

The construction of machine‘s electrical panel is in line with the IP 55 standard.

Operation:

-

Bottles to be loaded in horizontal position manually on the flow wrapping chain conveyor.

-

After that bottles will run on positive pusher feeding conveyor with uniform distance between the two bottles.

-

The speed of the conveyor is adjusted (synchronized) to maintain the desired speed with the help of variable drive.

-

The BOPP roll is fitted on the roll disc & is guided by the guide rolls.

-

The machine is operated with the help of switches.

Complete machine can be divided in following sub sections:

-

Machine Body & Components

-

BOPP film feeding system

-

Centre Sealing System

-

Horizontal Sealing & Cutting System

PACKING CONVEYOR

Salient Features:

-

Structure is made of SS 304 rigid construction.

-

Desired Length can be provided as per customer requirement.

-

SS elegantly matt finishing.

-

Adjustable height of conveyor belt, to align with other machine of the line.

-

Specially designed hard chrome roller with self-aligned bearings for longer life of conveyor.

-

Tension mechanism is provided for adjusting the belt tension.

-

AC variable drive for variable speed as per product size. The drive is fitted in the control panel below the conveyor.

-

Stopper arrangement at the end of conveyor for preventing falling/breakage of bottles.

-

Working space of 6, 9 & 12 inches on each side of the conveyor as per customer requirement.

-

Can be supplied with Castor wheels (OPTIONAL).

-

Usage of reliable & proven components such as Bonfiglioli/Motovario/Rotomotive Motor, Delta make AC variable drive etc.

Operation:

-

The conveyor transmits the products from the labeling machine, and brings till the end of conveyor for further process of packing.

-

During these process, the operators picks up the products & does necessary action like primary packing, secondary packing.

BOPP CARTON BOX TAP SEALING MACHINE

Technical:

Power Supply: 230 V AC / 50 Hz / Single Phase

Power Consumption: 660 Watt

Control System: Electrical Switchgear

Carton Size: L 120 mm Unlimited X W 120 mm To 450 mm X H 120 mm To 450 mm

Table Height: 750 mm

Speed: Up to 20 Box/Minute

Weight: 220 kg Approx.

Parts:

Body: Sheet Metal Steel Construction With Powder Coating

Mechanics: Made From MS Solid Material

Conveyor: MS Roller, Nylon Sandwich Belt

Features:

Easy To Operate

Easy Movable

Low Maintenance